Fragment Test System for Blast Research and Ballistic Experiments

The SATURN Digital Fragment Test System allows to save time and costs during test preparation, execution and post-test analysis of fragment distribution and velocity tests. One of the special advantages compared to traditional solutions is that the signals from the trigger foils (“make screens”/“break screens”) are acquired as digital signals. This simplifies the hardware setup and configuration and also allows high channel count tests at reduced costs per channel. Furthermore, the system offers unique diagnostic functions during the test preparation, which help to prevent costly failed tests.

The Digital Fragment Test System is based on the modular and expandable SATURN Series of data acquisition and control devices by AMOtronics. It is available in various housings from small portable systems up to multi-channel 19" chassis.

The system supports up to 192 digital I/Os (in/outputs) for connecting Fragment Test Trigger Foils (“make screens” / "break screens").

The fragment test in/outputs (“I/Os”) are provided in groups of 8 connectors per connection panel

(see picture below). Each I/O is equipped with a status LED and provides touch proof 45VDC supply for the connected foil.

Portable version of a SATURN Fragment Test System,

here in the smallest available housing and connections for 8 trigger foils (expandable).

In addition an example of a short-circuit foil (“make screen”) with diagnostic LED is shown.

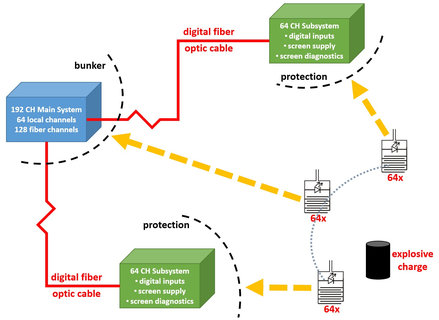

Depending on the size of the selected chassis up to 64 I/Os can be provided as “local channels” directly integrated in the main unit. Additionally (or alternatively) up to 128 I/Os can be provided as “remote channels” in two subunits (64 I/Os per unit).

Each subunit is connected with the main chassis via a single optical link. The optical high-speed connection allows to bridge long distances, as for instance between a bunker and the test field. Only one fiber cable pair is needed to transfer the signals from up to 64 fragment test foils (“screens”). During the test preparation this saves both time and costs.

The picture shows an example of a test setup with the main unit positioned in a bunker and

two subunits in the test field connected to the main unit via a single fiber-optic cable.

Each unit supports up to 64 fragment test foils with digital recording input,

touch-proof 45VDC output (power supply) and diagnostic function.

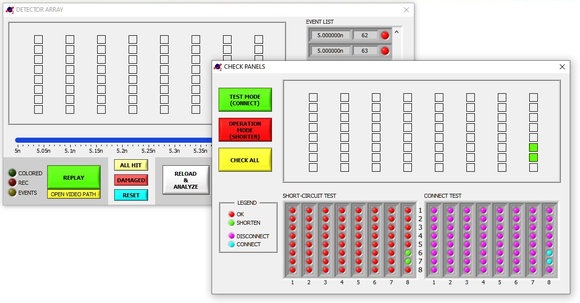

The system is operated via the “DETECTOR Control & Analysis Software” by AMOtronics. The software provides easy-to-use functions for setting up, performing and storing of Fragment Tests. It provides functions for interactive playback and analysis of recorded tests and also supports the creation of slow-motion videos.

A unique feature of the system is the extended diagnostic feature. In combination with a diagnostic LED implemented on the short-circuit foil (also called “make screen”) it allows to check the correct electrical connection and the state of each foil interactively via the software.

This diagnostic function simplifies the test setup. Faulty connections and defect foils can be detected quickly and easily in advance, which helps to prevent failed tests right from the beginning.

DETECTOR software for recording, analysis and playback of Fragment Tests with numerous Screens (Trigger Foils). The software supports nearly any geometric setup of the screens, as for instance matrix setups as shown above as well as linear, circular and also mixed setups.

The modular hardware and software concept serves a wide range of different test scenarios and allows to adapt to rising demands. As for instance the system can be equipped with additional channels if the required type or number of inputs changes over time.

Key Facts of the Fragment Test System

Hardware

- Different chassis sizes (small, mid or large)

- Integrated industrial CPU with display, keyboard and mouse connectors for stand-alone use

- Ethernet interface for network access and remote control

- Expandable configurations from 8 up to 192 digital channels (fragment test foils)

- Support of shortening foils (also called “short-circuit foils” or “make screens”) and opening foils (also called “break screens”)

- Supports both standard foils and foils equipped with diagnostic LED

- Optional additional analog and digital channels for data acquisition and control

- Signal acquisition with 40ns resolution (10ns at reduced channel count)

- Free configurable start triggers (fragment test foil, digital TTL input, analog input)

- Trigger synchronization from and to external subunits (remote inputs and outputs)

Digital I/O Panels for connecting Fragment Test Foils

- Up to 192 digital I/Os in groups of 8 per connection panel (also called “breakout”):

- Up to 64 local channels (directly integrated in main unit)

- Up to 129 remote channels in subunits (2 x 64)

- Only 1 fiber-optic link between main unit and subunits (64 digital channels per link)

- Robust rodent-proof and armored fiber-optic cables (for bridging nearly any distance)

- Plugged 2-wire I/O connector for fragment test foils (simple, fast and secure operation)

- Each I/O connector equipped with:

- Integrated power supply for the foil (touch-proof 45VDC)

- Status LED on the connection panel

- Foil diagnostic feature (connection status, open / short detection)

Analog and Digital Data Acquisition Inputs (optional)

- For recording of additional signals from other sensors:

- Local modules (directly integrated in main unit)

- SATURN Satellites (analog channels in separate housings, connected

via fiber-optic cable to bridge large distances)

- 200 kS/s … 2 GS/s measurement rate (depending on selected type of input module)

DETECTOR Software

- Easy-to-use configuration and control software (Windows™ based)

- Recording, saving and loading of signal data from foils, analog and digital channels

- Diagnostic support (check of foil connection and status before and after the test)

- Automated test analysis and generation of an event list (table of hits)

- Intelligent ringing filter (handles faulty multiple events caused by ringing)

- Export results as text files

- Flexible graphical display representing the foils using geometric elements:

- Color display of the states of the foils (connected/disconnected, open/short)

- Interactive scrolling through the test progress in the graphical display

- Automatic playback of the test in the graphical display

- Generation of slow-motion videos (recorded playback of the graphical display)

The preparation and execution of a fragment test is costly and time-consuming, especially when the number of channels is increasing.

With AMOtronics, your fragment tests become more efficient and reliable - at reduced cost per channel!

Download the product flyer (PDF)